Principle of the fluidized bed dryer a vibratory conveyor is leading the tobacco in an even layer through two drying zones.

Fluidized bed dryer design calculations xls.

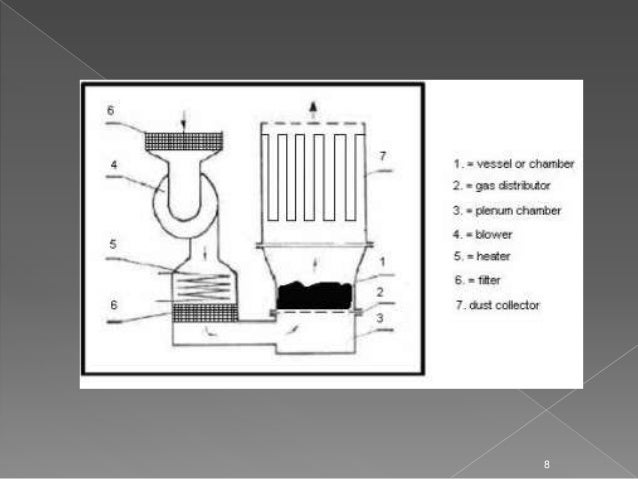

The process air coming from the perforated bottom of the trough creates a homogeneous fluidized carpet.

Fluidized bed dryer df gentle drying with a compact design the petkus fluidized bed dryer unites drying effectiveness with quality results.

In drying of wet solids the following main factors which essentially are used in process design calculation of dryers should be defined in accordance with mass and heat transfer principles process conditions and drying behavior.

Going to focus on fluidized bed dryers.

The new petkus fluidized bed dryer is a performance boost for high value seed.

Home freeze drying the good the bad and the ugly.

A domestic scale fluidized bed dryer is designed fabricated and used to measure the drying rates of wood chips.

4 1 description of the circulating fluidized bed and pilot plant 45 4 2 design of the cold model dual bed circulating system 50 4 3 windbox design 50 4 3 1 bed 1 and windbox design 51 4 3 2 bed 2 and windbox design 55 4 4 gas distributor plate 58 4 4 1 design criteria 58 4 4 2 porous distributor plate design 59 4 4 2 1 design of bed 1.

Fluid bed dryer design calculations 96 h2so4 tank storage nitrogen purge or dried air.

The equipment works on a principle of fluidization of the feed materials.

The best ways to dry compressed air quincy compressor.

Filtration gvs filter technology.

The fluidized bed dryer fbd is widely accepted in the pharmaceutical industry and is used during the granulation process to dry fine powder granules before these go forward to the rotary tabletting machine unlike other types of drying oven the fbd is fast acting and rapidly removes moisture from powder particles to a level that is acceptable for tablet formulation.

Fluidized bed dryer also called fluid bed dryer is a kind of equipment used extensively in the pharmaceutical industries to reduce the moisture content of pharmaceutical powder and granules.

Gas processing and treatment eptq.

Optimized product flow combined with cleverly designed airflow allows for a compact design and high drying efficiency.

Mechanism prior to design work is strongly recommended.

2 1 some advantages of fluidized bed reactor one advantage of using fluidized bed reactor as a dryer is the close control of conditions so that predetermined amount of free moisture may be left with the solids and to prevent dusting of the product during subsequent material handling operations perry and green 1998.

Design and development of fluidized bed dryer for domestic purposes.

Industrial dryers consume on average about 12 of the total energy used in manufacturing processes.

Shape of the instrument.

In manufacturing processes where drying is required the cost of drying can approach 60 70 of the total cost hamdullahpur et al 2002.

The annular based design gives a better product.